The Silent Staff Member: Why 2026’s Labour Crunch Demands a New Approach

We have just seen the headlines, and for anyone running a retail estate in the UK, they make for sober reading.

Here at our factory in Leicester, we talk to retailers and brand managers every day, and the mood has shifted. It is no longer just about selling more product; it is about survival in a high-cost environment.

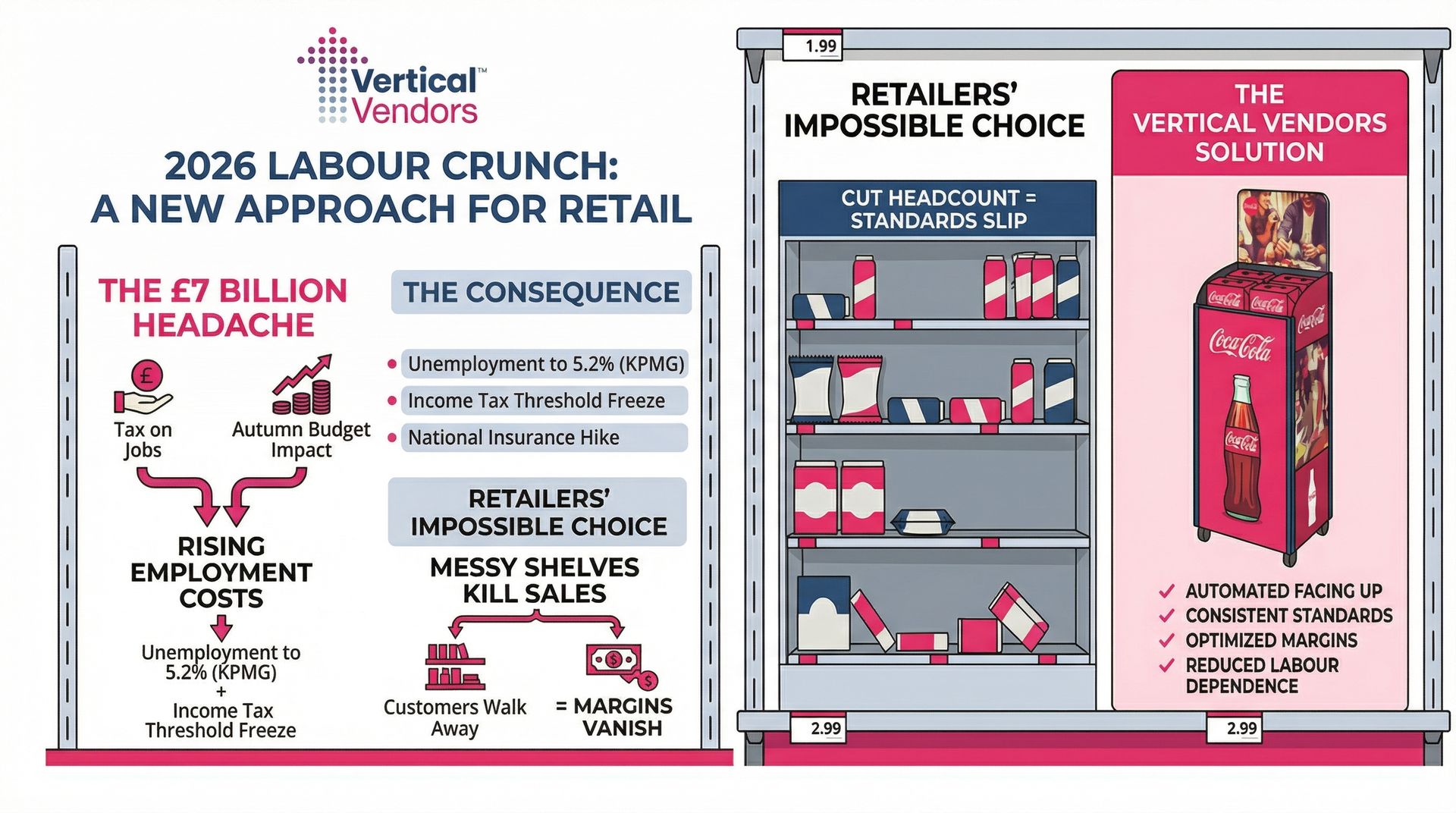

KPMG’s latest economic outlook, released on Monday, predicts that unemployment will tick up to 5.2% in 2026. This isn't just a number on a spreadsheet; it is a direct consequence of the "tax on jobs" that hit us in the Autumn Budget.

Between the freeze on income tax thresholds and the hike in National Insurance for pension schemes, the cost of employing people is skyrocketing. Retailers are being forced to make impossible choices. Do you cut headcount and let standards slip, or do you eat the costs and watch your margins vanish?

At Vertical Vendors,we and I believe there is a third option. It involves looking at your shelf not just as a storage space, but as an active member of your workforce.

The £7 Billion Headache

The numbers are stark, and they paint a worrying picture for the high street. The British Retail Consortium estimates that the industry faces a cost increase of over £7 billion in 2025 due to these policy changes. That is a massive hit to the bottom line, and it inevitably trickles down to store operations.

Yael Selfin, Chief Economist at KPMG UK, put it plainly in their recent analysis: “The outlook for growth in 2026 is subdued, reflecting the impact of a cooling labour market.”

For shop floor managers, this translates to fewer hours available for the basics. We have all seen it: the "facing up"—that endless task of pulling stock forward to keep shelves looking full—is often the first casualty when staff hours are cut.

But we know from decades of experience that messy shelves kill sales. When a customer sees a disorganised display, or has to reach into the back of a dark shelf to find a drink, they often just walk away. You cannot afford to lose that sale, but in this new economic climate, you also cannot afford the labour hours to prevent it.

The True Cost of "Facing Up"

Let’s do the maths. If you are paying a staff member £12 an hour, and they spend just 20 minutes a day manually shuffling stock forward, tidying messy cardboard displays, and restocking empty slots, that cost seems negligible.

But scale that up. Across 500 stores, that is thousands of hours of lost productivity every single week. That is time your staff could be spending helping customers, upselling, or managing fresh food waste. instead, they are battling gravity and untidy packaging.

This is where British engineering steps in to bridge the gap. We didn't design our units just to look good; we designed them to solve this specific operational problem. We engineered our spring-loaded systems to do one job perfectly: ensure your product is always at the front, always accessible, and always ready to sell.

Enter the Silent Staff Member

Think of a Vertical Vendor unit as a "silent staff member." It doesn't need a break, it doesn't cost you National Insurance, and it works 24/7.

Here is how it works:

- Automated Presentation: Every time a customer takes a can or a bottle, the next one automatically pops into place. The unit always looks full, even if there is only one item left.

- Zero-Labour Maintenance: There is no need for a staff member to walk the aisle and pull stock forward. The unit does it for them.

- High Capacity: Our units are designed to hold significant volume—often equivalent to 4 metres of shelving in a tiny footprint. This means restocking happens less frequently, further saving labour hours.

You effectively permanently "face up" your store for a one-off manufacturing cost. In a year where labour costs are the enemy, this is a strategic win.

Protecting Your Premium Image in a Volatile Market

It is not just about labour hours; it is about standards. As retailers look to premiumisation to protect their margins, the physical presentation of the product becomes critical. You cannot sell a premium energy drink or a craft beer if it is sitting in a torn, scruffy cardboard box.

We manufacture everything ourselves here in the UK to ISO 9001 standards. We use robust sheet metal, not flimsy card. Why? Because we know that in a high-traffic retail environment, displays get battered.

Cheap, single-use cardboard displays tear, sag, and look scruffy within days. They tell your customer that the product inside is an afterthought. Our units maintain a pristine appearance for over a decade.

By investing in permanent, automated merchandising, you are de-risking your operation against the volatility of the labour market. You are locking in high standards that are immune to wage hikes or recruitment freezes.

A Smart Investment for 2026

The KPMG report is a warning, but it is also an opportunity to rethink how we run our stores. The old model of throwing cheap cardboard and expensive labour at the problem is broken.

We are proud to support global brands and retailers from our base in Leicestershire. We have seen first-hand how switching to permanent, spring-loaded solutions changes the dynamic of a store. It frees up your team to do what humans do best—engage with customers—while the steel and springs handle the grunt work.

Ready To Get Started?

If you are looking to future-proof your retail estate against rising costs, let’s have a conversation about how we can automate your merchandising. Contact our team today.