M&S Just Dropped a Scope 3 Mandate (And It Changes Everything for Suppliers)

If you’ve been skimming the headlines this week, you might have missed a small but seismic shift in how British retail giants are handling their carbon footprint.

Marks & Spencer has officially launched RE:Spark, a major new decarbonisation programme in partnership with Schneider Electric.

On the surface, it looks like just another corporate sustainability press release. But if you are a brand supplying M&S—or any major retailer, for that matter—this is a signal you cannot afford to ignore.

The days of "marking your own homework" on sustainability are over. The focus has shifted aggressively from what retailers do in their own offices (Scope 1 and 2) to what you do in your factories and logistics networks (Scope 3).

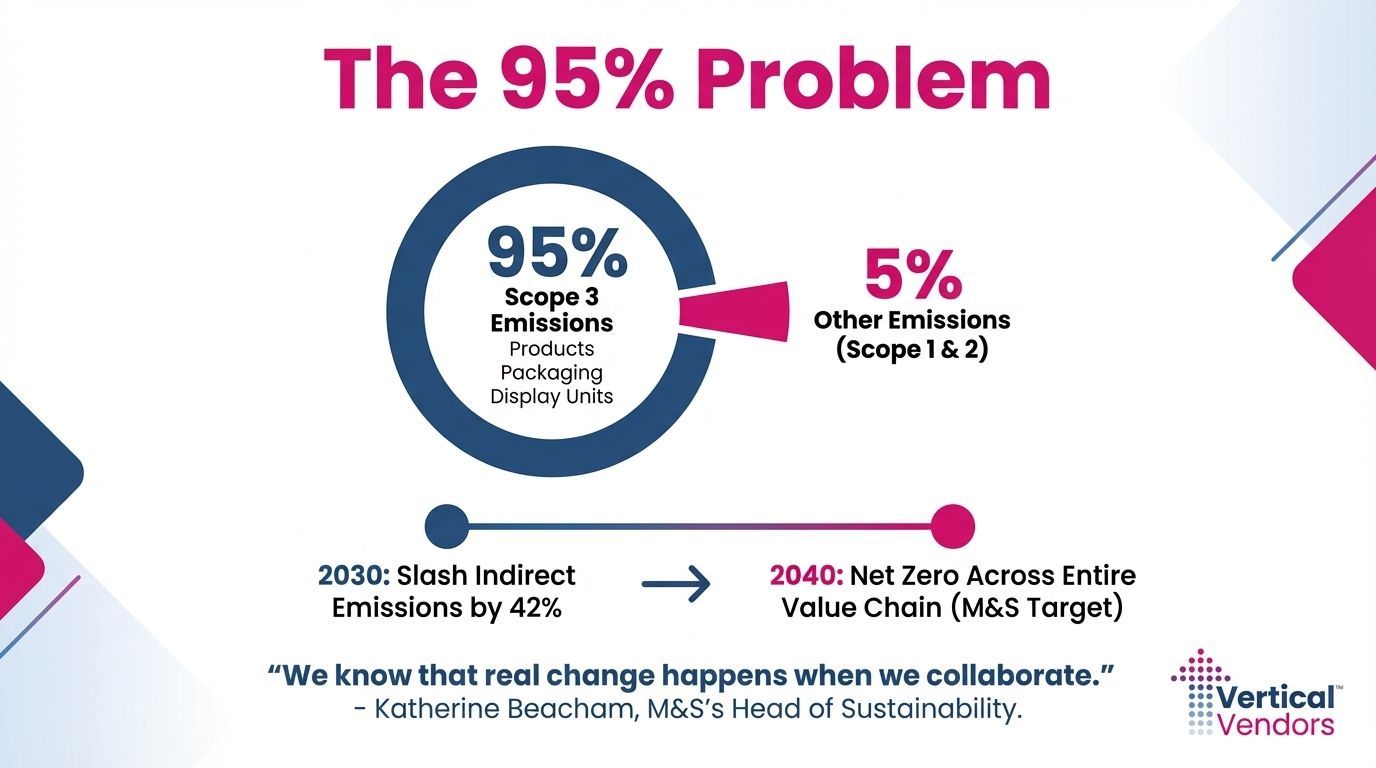

The 95% Problem

Here is the statistic that should make every supplier sit up and take notice: 95% of M&S’s total carbon footprint comes from Scope 3 emissions.

That isn't the electricity they burn in their stores or the fuel in their own lorries.

That is the carbon embedded in the products they buy, the packaging they use, and the display units that sit on their shop floors.

M&S has set a hard target: Net Zero across the entire value chain by 2040. To hit that, they need to slash these indirect emissions by 42% by 2030.

Katherine Beacham, M&S’s Head of Sustainability, put it plainly:

"We know that real change happens when we collaborate."

It’s a polite way of saying that if you want to stay on the shelf, you need to help them fix this number. "Collaboration" in this context effectively means "participation is mandatory."

Why Your Retail Displays Are a Scope 3 Nightmare

When brands audit their carbon footprint, they usually look at the product first. Is the bottle recyclable? Is the food locally sourced?

But they often overlook the elephant in the room: the merchandising itself.

For decades, the industry default has been to ship short-life cardboard displays (FSDUs) halfway around the world, or at least truck them across Europe. These units are heavy, inefficient to transport, and designed to fail. They last three weeks in a store (if they’re lucky) before being crushed and sent to a recycling centre—or worse, a landfill.

From a Scope 3 perspective, this model is a disaster.

- Manufacturing: You are constantly burning energy to make new temporary units for every single campaign.

- Logistics: You are essentially paying to ship fresh air and cardboard repeatedly, racking up transport miles.

- End-of-Life: The recycling process itself consumes energy.

If you are trying to present a low-carbon profile to a buyer at M&S, relying on disposable infrastructure is a gaping hole in your strategy.

The Durable "Cheat Code"

This is where the conversation needs to shift from "recycling" to "reuse."

We have always argued that a retail display should be an asset, not a consumable. When you switch to a permanent, spring-loaded metal unit, you flip the script on Scope 3 emissions.

Instead of manufacturing 15 different cardboard units over a year, you manufacture one steel unit that lasts for ten.

That creates an immediate, measurable reduction in your carbon footprint. You eliminate the manufacturing emissions of those 14 cancelled cardboard runs. You remove the logistics emissions of shipping them to stores.

Furthermore, manufacturing location matters more than ever. Importing display equipment from the Far East adds a massive carbon penalty to your ledger before the unit even hits a UK distribution centre. Sourcing from a UK manufacturer drastically shortens that supply chain, removing thousands of miles of ocean freight from your Scope 3 calculation.

Looking Beyond the Spreadsheet

The RE:Spark initiative is currently focused on renewable electricity adoption, particularly in fashion supply chains.

However, the precedent is set. The forensic lens M&S is applying to energy usage will inevitably widen to include materials and logistics.

Retailers are looking for "easy wins" to report to their shareholders. A supplier who can walk into a pitch meeting and say, "We have removed 50 tonnes of single-use cardboard from our supply chain and cut logistics emissions by 30% by switching to UK-made permanent displays" is going to be a lot more attractive than one who is still stuck on the disposable treadmill.

It helps that these permanent units also happen to keep shelves tidy and drive sales—a nice bonus when you’re trying to justify the investment. See our case studies

The Future is Fixed

We built our business in Leicester UK because we believed that local manufacturing was the only way to guarantee quality and true sustainability.

It turns out, it’s also the best way to future-proof your business against the rising tide of environmental regulation.

The M&S announcement is just the start. The scrutiny on Scope 3 is only going to get tighter. The brands that start treating their merchandising infrastructure as a long-term investment, rather than a monthly expense, will be the ones that thrive in this new era of accountability.

Don't wait for the next mandate to drop. Fix your display strategy now.

Ready To Get Started?

If you want to reduce your carbon footprint and secure your place on the shelf, let's talk about a permanent solution. Contact us today to discuss your sustainable merchandising strategy.